Self-Destructing Plastics – Award Winning Recycling Solution

A fantastic number of items that were once made from glass, metal, wood, plant fibers, animal hair and animal bone are now being made out of plastics. The creation of synthetic plastics started in the early 1900s. In the years that followed chemists and engineers created many new plastics with properties that matched the look, strength and other characteristics of each material listed above.

Our Plastics Problem

A recent article in the Smithsonian Magazine indicates that the US was only able to recycle just 5 to 6 percent of the 40 million tons of plastic waste that its citizens generated in 2021. So much of the plastics that don’t get recycled end up in the oceans of the world and over time they do break down into micro-sized grains that are consumed by marine life.

For over 20 years scientists have warned that these microplastic particles could be dangerous. Most past studies focused on the dangers of microplastics to marine life. New studies are now underway to determine the dangers of microplastic and even small nano-plastic particles to animal life. Properly removing and fully recycling plastic right down to the nano-sized particles might soon be possible.

A Contest to Stimulate Innovation

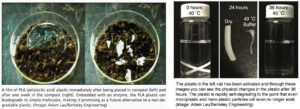

NASA Tech Briefs Magazine launched a yearly Create the Future Design Contest in 2002. The stated goal of these contests is to “stimulate and reward engineering innovation” in multiple areas of technology. This column is going to describe the amazing technology that the 2021 grand prize-winning team created and entered into the Sustainable Technologies/Future Energy category of the contest. The team of researchers from the University at California, Berkeley campus actually developed enzymes that can make plastics fully degradable. See photos 1 and 2. The enzymes that they created are designed to be embedded into new plastics during the manufacturing process.

When these plastics are ready to be recycled, the self-destruct enzymes can be activated. Once activated, the plastics that they are embedded in immediately start to decompose. In just a few days the original plastic will be untraceable and when the decomposition process is complete all microplastic and nano-plastic particles will also be untraceable.

The research that they included in their documentation showed that the enzymes are completely stable, can completely decompose the plastics they are embedded in, and before activation have no effect on the plastics properties. In a special facility their process would also allow for the recapturing of the original plastic molecules so they can be used to make new plastics.

A Look to the Future

Since winning this award and completing his Ph.D. at Berkeley, Dr. Hall started Intropic Materials to take his team’s research from proof of concept to manufactured products. His company now has a lab at Lawrence Berkeley National Laboratories and to quote him his team “is focusing on scaling up from grams to Kilograms to tons and beyond so we can actually start getting these enzymes into the materials”. One can assume that a lot of research, testing, and government safety approval will need to take place before plastic with embedded enzymes becomes products that you can actually purchase.

Easy to print PDF

https://www.technologytoday.us/Self-Destructing_Plastics-A_2021_Award_Winning_Recycling_Solution.pdf

Taking it a step Further

Your teacher will adjust this research activity so it is grade appropriate. Assign students to specific materials and determine how your findings will be presented to your class.

Research Activity

So many objects that were once made out of glass, metal, wood, plant fibers, animal hair and animal bone are now being made out of plastics. Which plastics properties enticed companies to start making their products out of plastics rather than a material listed above.